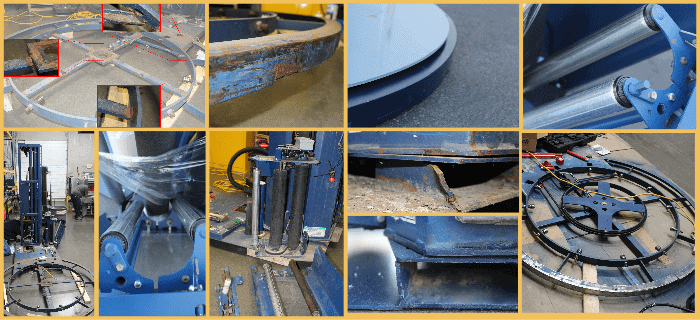

The Best Packaging team recently completed a full refurbishment, taking a severely damaged stretch wrapper and restoring it to like-new condition.

This Q300 Turntable Stretch Wrapper arrived at Best Packaging in considerably rough condition. In its previous operation, it had suffered a forklift collision that left the turntable base compromised. Due to a lack of care and preventative maintenance, it developed considerable rust in the structure and key-wear components. The pre-stretch rollers, which are instrumental in creating appropriate stretch elasticity and containment force, were inoperative.

Upon refurbishment, all of Best Packaging’s resale equipment receives a 5-point inspection. This guarantees that our “gold star” machinery has undergone:

- Safety inspection and testing

- Electrical component assessments

- Mechanical assessments

- Pneumatics testing

- Esthetic enhancements (fresh paint, rulers, and labels)

After much hard work and attention to detail, the Q300 is now fully restored and ready to wrap pallets in its new production facility home.

The refurbished machinery market is both economically and environmentally friendly. It allows used equipment to elongate its useful life. Sellers are provided with positive cash flow and purchasers receive cost savings.

You can help Best Packaging recycle idle machinery by contacting us when you’re looking to update or liquidate your inventory.

If you are interested in selling, please contact our sales team at sales@bestpackaging.com.

If you are looking to purchase certified refurbished equipment, please visit our refurbished inventory page.

What’s your take? We welcome guest bloggers! E-mail socialmedia@bestpackaging.com if you’d ever like to collaborate.