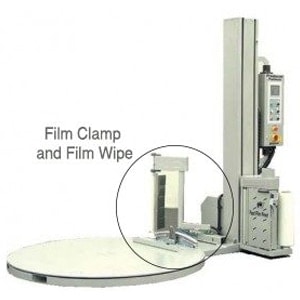

Description:

This is the most commonly used stretch wrapper. Turntable stretch wrappers use a platform to rotate the pallet while the film is being dispensed at the carriage. The carriage typically moves up and down encompassing the entire load. There are four different types of turntable stretch wrappers.

Best Application:

Square, stable loads.

Spaced Needed:

(Approx.) Length: 7-12ft | Width: 8-10ft | Height: 8-11ft*

* Varies depending on the wrapper

Types of Turntable Stretch Wrappers

Low Profile

- A low profile machine is best fit for pallet jacks applications.

- The platform usually stands no more than couple inches from the ground.

- A ramp may be added as an additional customized option.

High Profile

- A high profile stretch wrapper is best fit for forklift applications.

- Unlike a low profile, the turntable has an elevated design and provides easier loading and positioning due to its height.

- Can be easier to maintain and repair.

Semi-Automatic

- Semi-Automatic stretch wrap machines require an operator to load the machine, attach the film to the load, start the machine, cut the film, and secure the film tail to the load.

- Semi-automatic stretch wrappers are ideal for manufacturing industries that wrap up to 20 loads per day, otherwise you should use a full-automatic.

- Semi-automatic stretch wrappers are designed for use with a forklift or a pallet jack.

Automatic

- Automatic stretch wrappers don’t require an operator.

- High speed automatic stretch wrappers usually incorporate conveyors to increase productivity.

- These stretch wrappers can keep up with the most demanding production rates (120 loads per hour with a conveyor).

- Automatic stretch wrappers apply and cut the film, so the only thing you need to do is change the film roll.

We represent a variety of different brands in order to match the best system to your unique production needs. The photos on this page are provided to assist you in choosing the correct machine for your operation/application. These images are representational and are not a perfect match to the actual product, machine, or system Best Packaging will quote/sell. Colors and photo size may vary based upon your screen resolution and other computer settings outside of Best Packaging’s control. Additionally, the photo may differ from the actual product quoted/sold due to distribution agreement limitations.

To determine what solution is best for your loads, contact Best Packaging at (888) 930-BEST.