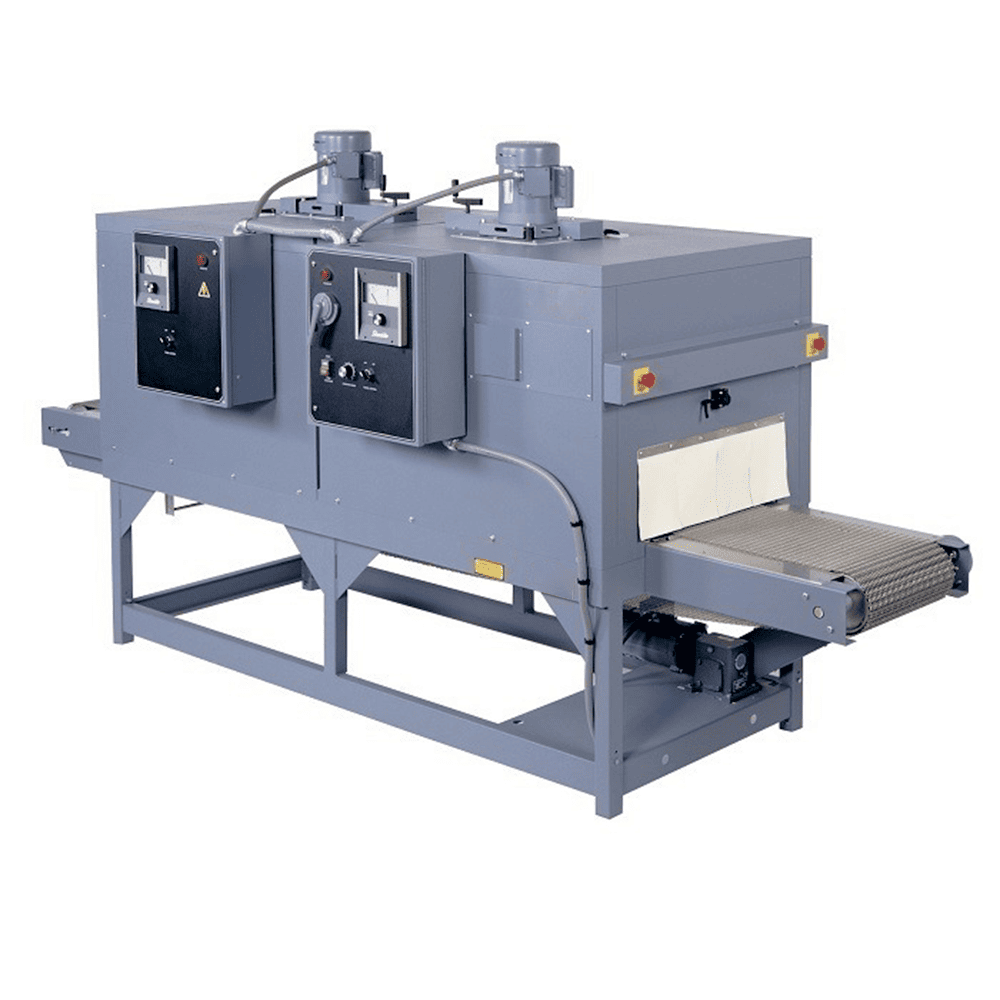

Steam shrink tunnels disperse heat proportionally throughout the whole surface of the film as it envelopes the container going through the tunnel.

Steam Tunnels are ideal for applications with complex package infrastructure, as the heat permeates every crevasse, allowing the film to adhere to as much surface area as possible. Due to the steam- temperatures are lower, leaving the environment within the tunnel not as harsh, typically allowing for a lowered maintenance schedule across the life of the machine.