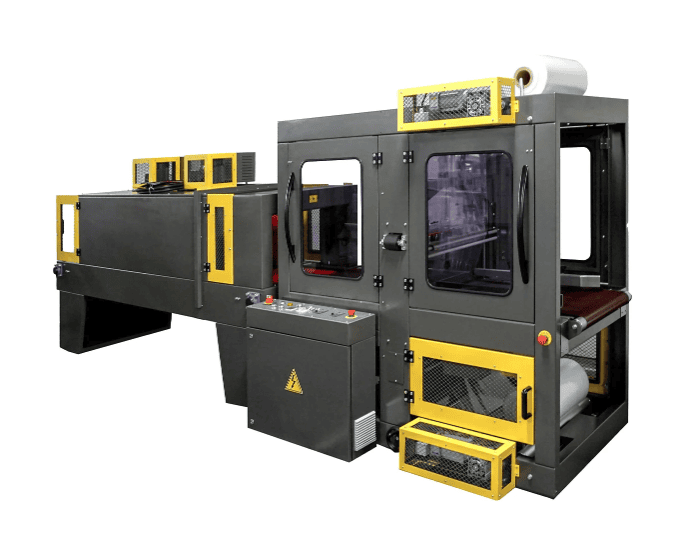

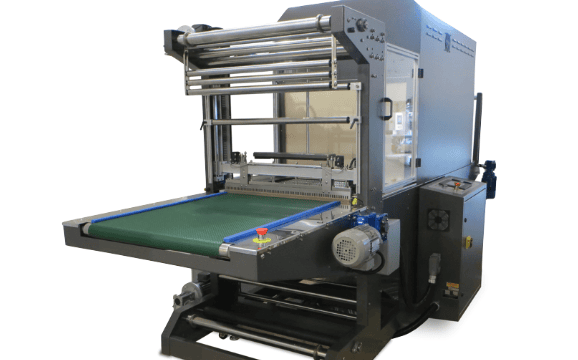

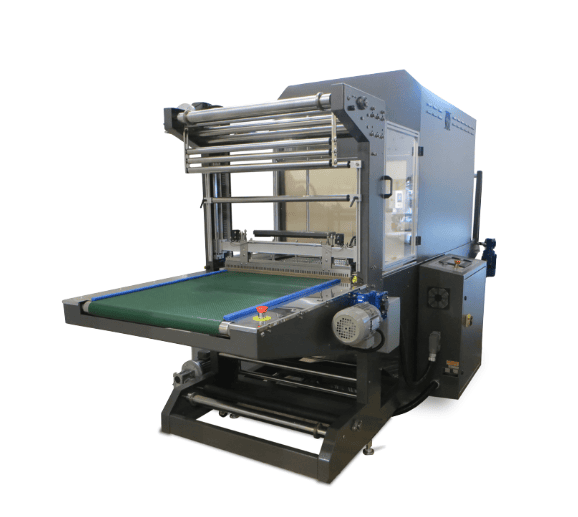

In-Line Poly Bundlers + Shrink Tunnel

Fully Automatic In-Line Poly Bundler with Shrink Tunnel. As product travels down infeed conveyor a photo eye is activated by the product and the film is automatically advanced. Once the product has passed through the seal area, the seal bar is activated and seals product. At this point the package is picked up by the tunnel conveyor belt and automatically transferred into the shrink tunnel. Production speeds of 10 to 15 PPM can be obtained depending on package length, film thickness