Executive Summary

When an aging Cousins Hercules stretch wrapper lost it’s PLC program, it was destined for the junkyard until Best Packaging’s used their expert programming skills to give it a second life.

Customer Background

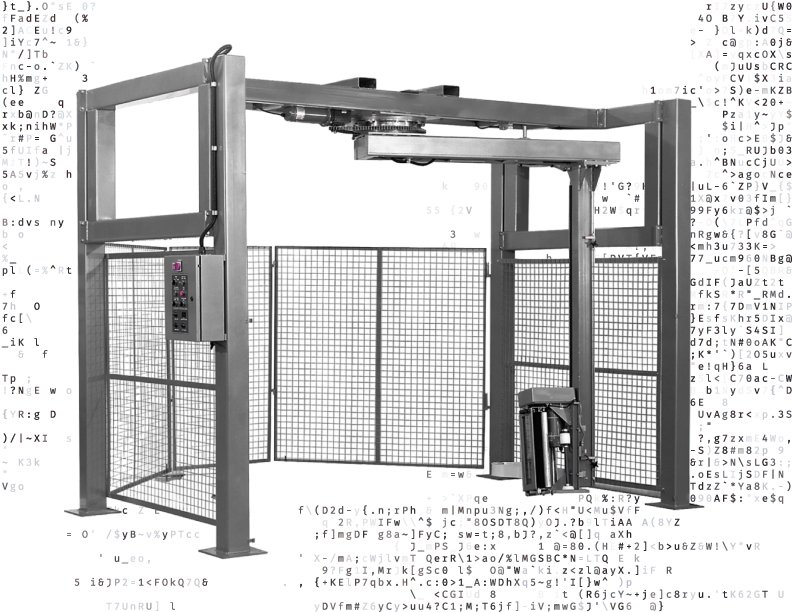

The customer specializes in asphalt roofing and supplies such as caulks, coatings and adhesives. Their facility uses a Cousins Hercules stretch wrapper to prepare large, heavy pallets for shipment.

Challenges

Best Packaging was called to the warehouse when the customer reported a malfunctioning film clamp in their Hercules stretch wrapper. When Best Packaging’s service technician arrived on site, he quickly recognized this was more than a simple mechanical error. The PLC on this Cousins machine had somehow lost all memory of its programming.

To further complicate the issue, the PLC on this particular Hercules stretch wrapper was so old, it was unable to be supported by Allen Bradley, the gold standard in programmable logic controllers. Without parts readily available for this obsolete system, the only options were to install a brand new PLC, or to rebuild one of the same vintage as the original.

Solution

Challenges such as narrow timeframe and scarcity of vintage parts would have made it difficult to rebuild the outdated PLC. The customer agreed that the best solution would be for Best Packaging to specify and program a new PLC.

7 business days after the initial phone call, the new PLC arrived at Best Packaging’s workshop, where technicians began the complex task of writing new programming for the new PLC. As it turns out, the gravity conveyor logic that the customer needs was not included in the new PLC because it was added to the stretch wrapper after the machine was installed at the customer’s facility. Best Packaging worked with Cousins, the machine manufacturer, to rewrite the logic for this new PLC.

The Results

Equipped with a new, fully programmed PLC, Best Packaging visited the facility to install it in their machine. The PLC was installed and the Hercules stretch wrapper was tested. After successfully wrapping 10 pallets, the customer confirmed the machine functions fully to their satisfaction.

FUTURE APPLICATION

Best packaging is committed to supplying businesses with the absolute best in end-of-line equipment repair. Our quick response time sets us apart. We understand your business cannot afford to lose a day of productivity. Therefore, we pride ourselves on providing customers with efficient 24/7 emergency repairs. If you experience breakdown, Don’t wait! Call best packaging today! 888-930-best.