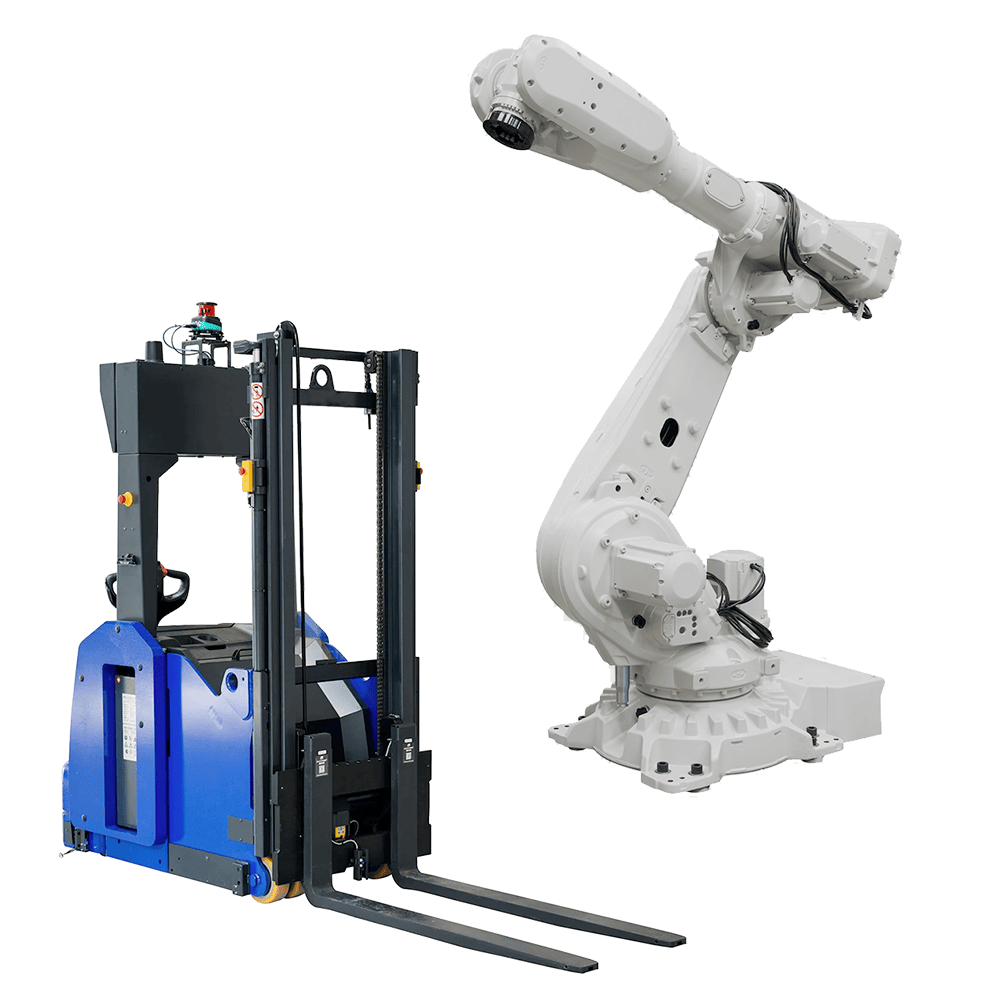

Industrial Automated Guided Vehicles (AGVs) are autonomous mobile robots designed for material handling and transportation within industrial operations.

These vehicles are equipped with sensors, cameras, and navigation systems that enable them to operate without human intervention. Previously, AGVs often followed predetermined paths configured by magnetic strips, guide wires, or laser markers. Most recently, AGVs have now begun integrating user-friendly technology, augmented by AI in order to map their surroundings in real time. They can be trained to observe an environment, allowing them to navigate through warehouses, manufacturing facilities, and distribution centers with precision and safety.

AGVs are utilized in various applications to streamline logistics and enhance operational efficiency. In manufacturing, AGVs play a key role in automating the movement of raw materials, work-in-progress, and finished goods, optimizing production workflows. In warehouses and distribution centers, AGVs efficiently transport goods between storage locations, aiding in inventory management and order fulfillment. The versatility and automation capabilities of AGVs make them ample candidates to streamline current industrial material handling processes, contributing to increased productivity and reduced operational costs.