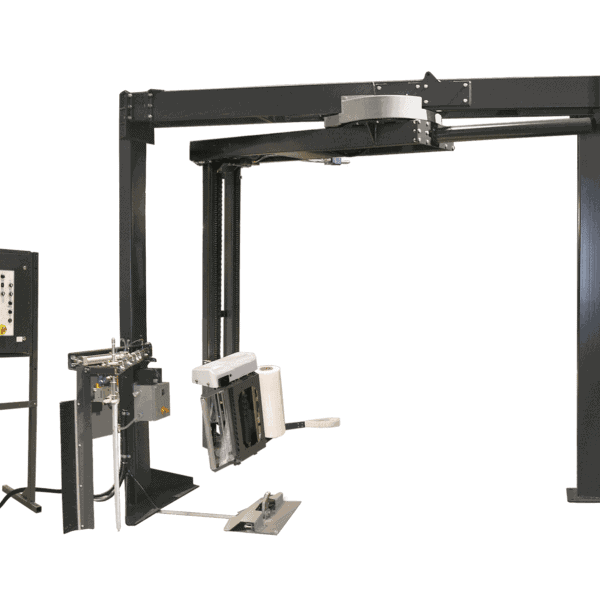

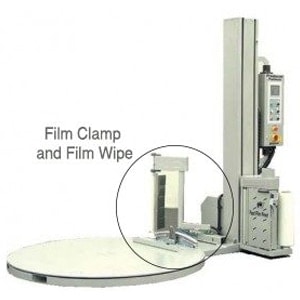

Description:

Robotic stretch wrappers are self-propelled, portable stretch wrappers that apply film as it navigates around the load. Robotic stretch wrap machines typically include a safety bumper to prevent crushing the corners of your load.

Best Application:

No minimum load weight.

Space Needed:

Portable, takes up very little floor space. Can easily be moved.